Are your valves not working properly? There are causes that cause these problems. Some faults already occur during assembly, for example, when the valve spring is inserted incorrectly from the axis of movement of the valve. Abnormal lateral pressure is applied to the valve from the side, the valve cannot move freely and starts to bend until it breaks completely. The consequences can be fatal.

The list of causes for possible valve failures is described below in the article.

INSTALLATION AND ADJUSTMENT ERRORS

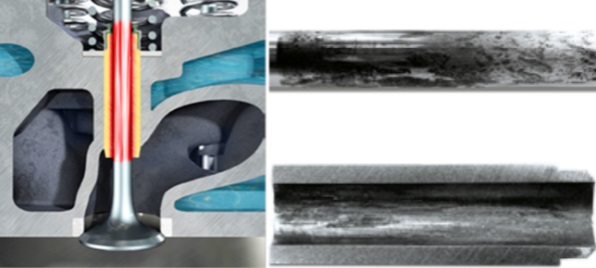

Incorrect valve lash adjustment

Cause: The valve clearance has been adjusted too tightly or the maintenance intervals have been exceeded.

Consequence:: The valve no longer closes properly. Combustion gases flowing past the valve seat heat up the valve disc. The valve disc overheats and burns out in the seat area.

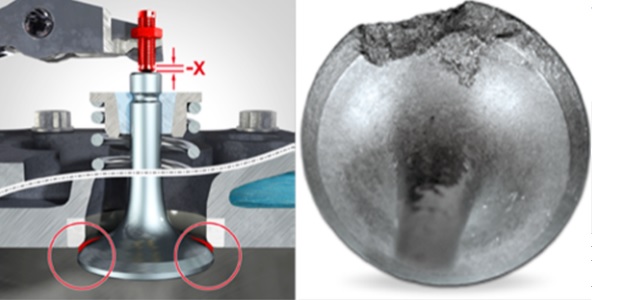

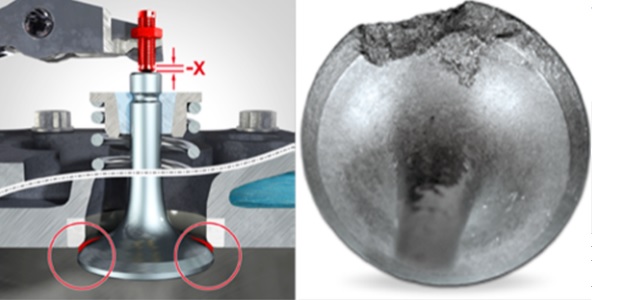

Valve spring Installation error

Cause: The spring was not inserted correctly during installation. The canting led to a lateral bending moment (M) at the valve stem.

Consequence: The resulting bending stress has led to the destruction of the valve guide and finally to the breakage of the valve stem end.

Hydraulic tappet assembly error

Cause: After fitting the tappets, the prescribed waiting time before starting the engine (at least 30 min.) was not observed. The excess oil in the tappet working chamber did not have enough time to escape.

Consequence: When starting the engine prematurely, the valves hit the pistons, are bent or break.

MACHINING ERROR

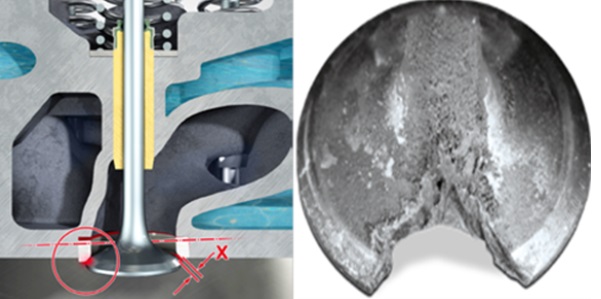

Misalignment of valve seat ring or valve guide

Cause: The valve seat or guide has not been re-machined centrically.

Consequence: The valve does not close properly, overheats and burns out in the seat area. Due to one-sided loading of the valve disc, permanent fractures can also occur in the area of the cove.

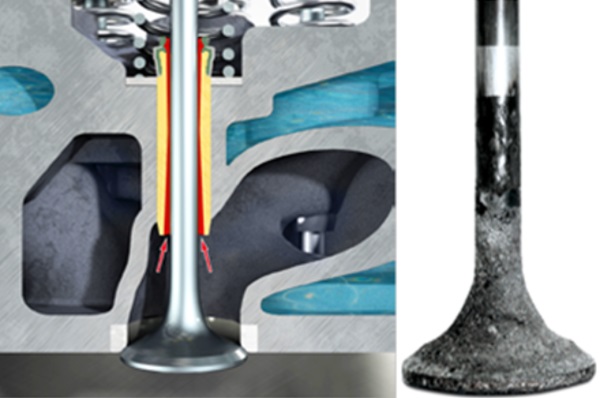

Too much valve guide clearance

Cause: The valve guide clearance is too large because the valve guides are heavily worn or were rubbed down too much during repair.

Consequence: Considerable coking can occur in the stem guide area due to hot gas radiation. The valve becomes sluggish, no longer closes and overheating (burns, shot channels) occur on the seat surface.

Valve guide clearance too small

Cause: When the valve guides were replaced, the guide diameter was too narrow.

Consequence: Insufficient lubrication, sluggishness and seizure of the valve stem in the guide. Consequential damage can include overheating in the disc or seat area.

INSTALLATION OF WORN PARTS

Use of worn valve cone pieces

Cause: Old, worn valve cone pieces were used when the valves were replaced.

Consequence: When reusing worn cone pieces, the clamp fastening can loosen in use. This results in fretting corrosion on the stem and weakening of the valve in this area. This can lead to permanent vibration fractures.

Installation of damaged rocker arm / finger follower

Cause: The force from the rocker arm is applied off-centre to the shaft end face of the valve.

Consequence: One-sided shaft and shaft wear occurs. The transverse force load on the valve stem caused by the eccentric force application leads to permanent fractures in the area of the clamp fastening.

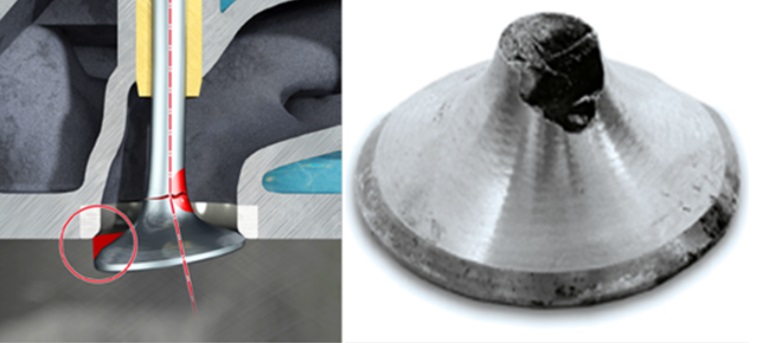

Installation of bent valves

Cause: Due to the bending of the valve stem, the valve seat is supported on the seat ring from one side.

Consequence: Due to one-sided load, bending fatigue stresses and fatigue fractures occur in the fillet radius at the transition to the stem.

COMBUSTION DISTURBANCES

Valve overload due to combustion disturbances

Cause: Due to combustion disturbances, strongly increased pressure and temperature loads occur in the combustion chamber.

Consequence: The valve disc cannot withstand the high thermal-mechanical stresses and bends inwards. This leads to so-called tulip formation and fractures in the disc area.

Here you will find an overview of all valves in the K Motorshop range.

This article is based on the service information from TRW (Reference number:50003976-10).

Don‘t forget to register and sign in, to see your individual prices.

![$languages[$currentLang]->langNam](/images/flag/gb.png)